A plane door at 16,000ft had four key bolts missing when it blew out.

The aircraft experienced a sudden drop in cabin pressure following a frightening event.

February 6th 2024.

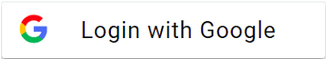

In the middle of a flight in January, the door of a plane suddenly blew out, causing panic and chaos among the passengers on board. According to a recent report, the door was missing four critical bolts that were meant to secure it to the fuselage. This incident occurred on a Boeing 737 Max, which was forced to make an emergency landing shortly after taking off from Portland International Airport.

The plane was carrying a total of 180 people, including 174 passengers and six crew members, when the door blew open just six minutes after departure. The National Transportation Safety Board, in its initial findings, stated that the missing bolts were responsible for the door panel breaking away from the aircraft and causing a rapid loss of cabin pressure. However, the pilot was able to skillfully land the plane safely, averting a major disaster.

Upon further investigation, it was discovered that the door panel had been removed and reinstalled during the production process. Spirit AeroSystems, the supplier for Boeing, had manufactured and installed the door plug before delivering it to the aerospace giant. However, it was later removed due to damage and then reinstalled, with photos suggesting that at least three of the locking bolts were not put back in place.

Boeing CEO Dave Calhoun has taken responsibility for the incident, admitting that there were some manufacturing errors. He has also expressed his determination to regain the trust and confidence of their customers, regulators, and congressional leaders. Meanwhile, experts have been examining the detached panel to determine the exact cause of the incident.

In a statement, Boeing has acknowledged the NTSB's findings and has promised to review them promptly. They have also assured full cooperation with both the NTSB and FAA investigations. The FAA, on the other hand, has taken a closer look at Boeing's manufacturing procedures, specifically for the 737 Max, and has temporarily halted the production until they are satisfied with the quality control.

The FAA administrator, Michael Whitaker, has stated that their main concerns are figuring out what went wrong with the Max 9 and what is happening with the production at Boeing. This is not the first time Boeing has come under scrutiny for their quality control processes, as there have been other incidents reported, such as loose bolts and fittings on other planes. These recent issues have raised doubts about the construction of this particular aircraft.

In the past month alone, there have been several mechanical incidents reported on Boeing planes, including a United Airlines flight that had to make an emergency landing due to a cracked windshield. A similar issue occurred on a Boeing 737-800 in Japan just weeks before. As the investigation continues, there are serious concerns about the safety and reliability of these planes, and steps must be taken to ensure that such incidents do not occur in the future.

The plane was carrying a total of 180 people, including 174 passengers and six crew members, when the door blew open just six minutes after departure. The National Transportation Safety Board, in its initial findings, stated that the missing bolts were responsible for the door panel breaking away from the aircraft and causing a rapid loss of cabin pressure. However, the pilot was able to skillfully land the plane safely, averting a major disaster.

Upon further investigation, it was discovered that the door panel had been removed and reinstalled during the production process. Spirit AeroSystems, the supplier for Boeing, had manufactured and installed the door plug before delivering it to the aerospace giant. However, it was later removed due to damage and then reinstalled, with photos suggesting that at least three of the locking bolts were not put back in place.

Boeing CEO Dave Calhoun has taken responsibility for the incident, admitting that there were some manufacturing errors. He has also expressed his determination to regain the trust and confidence of their customers, regulators, and congressional leaders. Meanwhile, experts have been examining the detached panel to determine the exact cause of the incident.

In a statement, Boeing has acknowledged the NTSB's findings and has promised to review them promptly. They have also assured full cooperation with both the NTSB and FAA investigations. The FAA, on the other hand, has taken a closer look at Boeing's manufacturing procedures, specifically for the 737 Max, and has temporarily halted the production until they are satisfied with the quality control.

The FAA administrator, Michael Whitaker, has stated that their main concerns are figuring out what went wrong with the Max 9 and what is happening with the production at Boeing. This is not the first time Boeing has come under scrutiny for their quality control processes, as there have been other incidents reported, such as loose bolts and fittings on other planes. These recent issues have raised doubts about the construction of this particular aircraft.

In the past month alone, there have been several mechanical incidents reported on Boeing planes, including a United Airlines flight that had to make an emergency landing due to a cracked windshield. A similar issue occurred on a Boeing 737-800 in Japan just weeks before. As the investigation continues, there are serious concerns about the safety and reliability of these planes, and steps must be taken to ensure that such incidents do not occur in the future.

[This article has been trending online recently and has been generated with AI. Your feed is customized.]

[Generative AI is experimental.]

0

0

Submit Comment